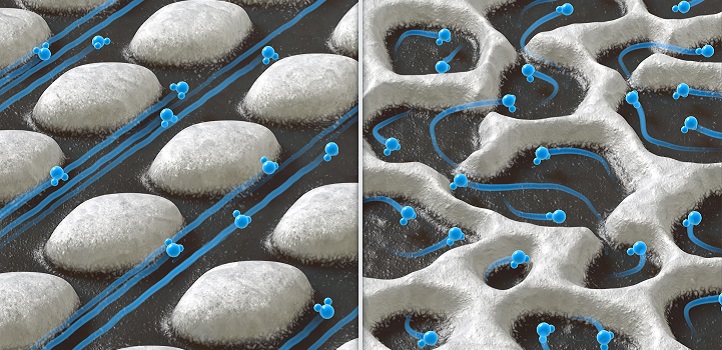

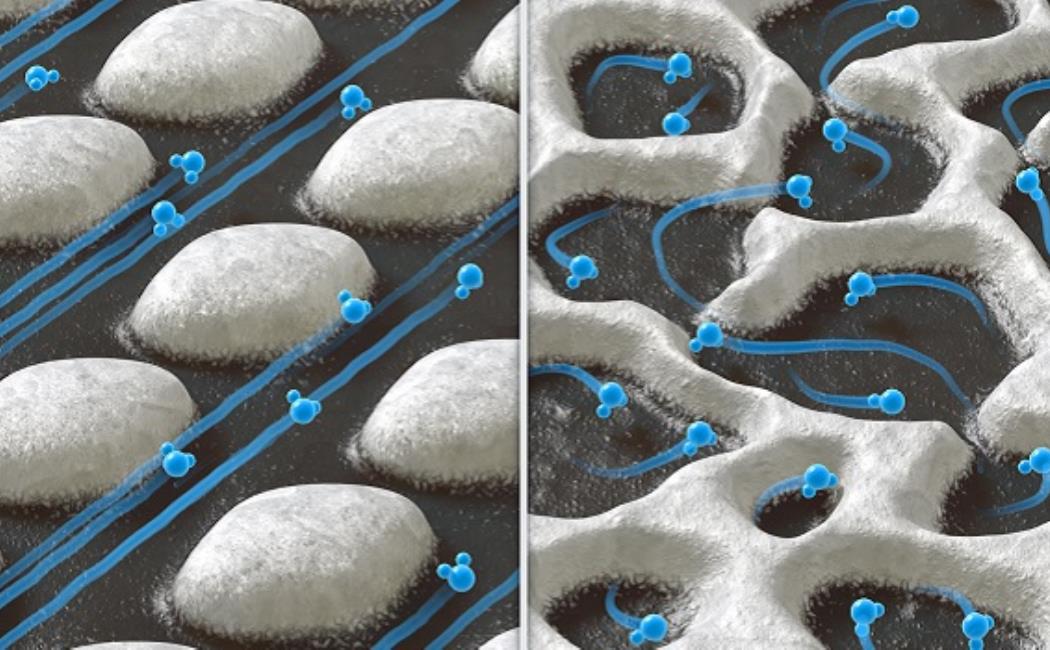

Schematic depictions of membranes with ordered (left) and disordered (right) channel structures.

Reproduced with permission from reference 1 © 2018 Xavier Pita

Self-assembled channels in a polymer membrane could greatly enhance extraction of water from gases.

Removing water vapor from air and other gas mixtures, which is crucial for many industrial processes and air conditioning, could become cheaper and more effective through polymer membrane technology now developed at KAUST.

“We have made a polymer

film with extremely high permeability for water vapor while presenting an effective barrier for other gases,” explains Faheem Akhtar, a KAUST Ph.D. student.

The researchers found a way to create tiny nanochannels in the membrane structure that they describe as highways for

water molecules. The channels attract water and divert it away

for extraction, leaving dry gases behind. “The water transport is extremely fast,” Akhtar adds. The membranes are composed of a commercial polymer called NexarTM. This is a block copolymer that assembles when short blocks of one repeating

molecular unit become sequentially linked with short blocks of another type of unit. The chemical structure of the blocks controls the interaction with water vapor and other gases.

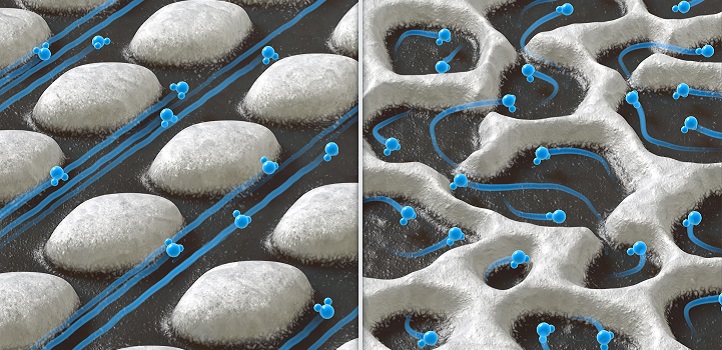

The key innovation, however, was the discovery that the fine structure of bumps and ridges in the membranes can be controlled by varying the conditions in which the polymer self-assembles. Changing the solvents used during the polymer formation

generates membranes with a variety of ordered or disordered channels (see images).

“Getting the right polymer morphology was very challenging and interesting,” says team leader Klaus-Viktor Peinemann. He explains that the polymer contains water-friendly and water-repellent sections. When prepared using appropriate

solvents, the water-friendly sections orient themselves like pearls on a string, forming the highways for water transport.

“It took us a long time to find the right conditions,” Akhtar points out. To succeed, theoretical understanding of the chemical interaction between the chosen solvents and the polymer was combined with a fair bit of trial and error.

Through science and perseverance, the researchers eventually identified a procedure to make ordered structures that yield a six-fold increase in water permeability compared to disordered membranes.

Having demonstrated the basic potential of the membrane technology, the team now plan to scale-up the manufacturing process and to test it in realistic industrial applications. The commercial opportunities are considerable. More effective dehumidification

methods could drastically reduce the energy consumption of an energy-intensive procedure.

Akhtar and colleagues developed the advance in collaboration with scientists from both Physical Sciences and Engineering and Biological and Environmental Science and Engineering Divisions.

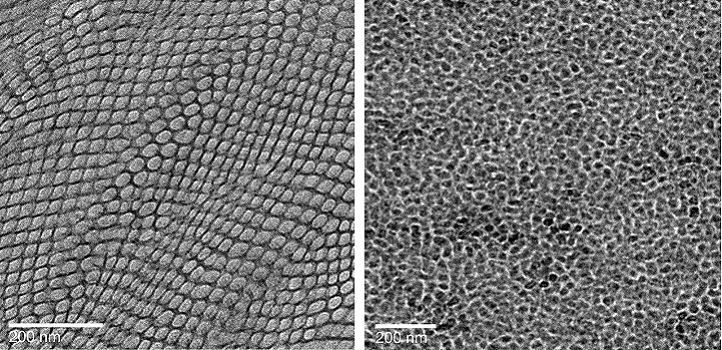

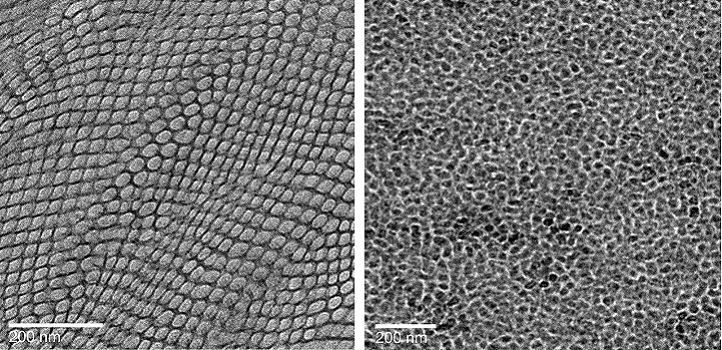

Electron micrograph images of membranes with ordered (left) and disordered (right) channel structures.

Reproduced with permission from reference 1 ©2018 Elsevier

Selected Publications

- Highways for water molecules: Interplay between nanostructure and water vapor transport in block copolymer membrane...

F.H. Akhtara, H. Vovushuab, L.F. Villalobosa, R. Shevate, M. Kumara, S. Pereira Nunes, U. ...

Journal of Membrane Science, volume 572, pp. 641-649, (2019)

The researchers found a way to create tiny nanochannels in the membrane structure that they describe as highways for

The researchers found a way to create tiny nanochannels in the membrane structure that they describe as highways for  water molecules. The channels attract water and divert it away

for extraction, leaving dry gases behind. “The water transport is extremely fast,” Akhtar adds. The membranes are composed of a commercial polymer called NexarTM. This is a block copolymer that assembles when short blocks of one repeating

molecular unit become sequentially linked with short blocks of another type of unit. The chemical structure of the blocks controls the interaction with water vapor and other gases.

water molecules. The channels attract water and divert it away

for extraction, leaving dry gases behind. “The water transport is extremely fast,” Akhtar adds. The membranes are composed of a commercial polymer called NexarTM. This is a block copolymer that assembles when short blocks of one repeating

molecular unit become sequentially linked with short blocks of another type of unit. The chemical structure of the blocks controls the interaction with water vapor and other gases.