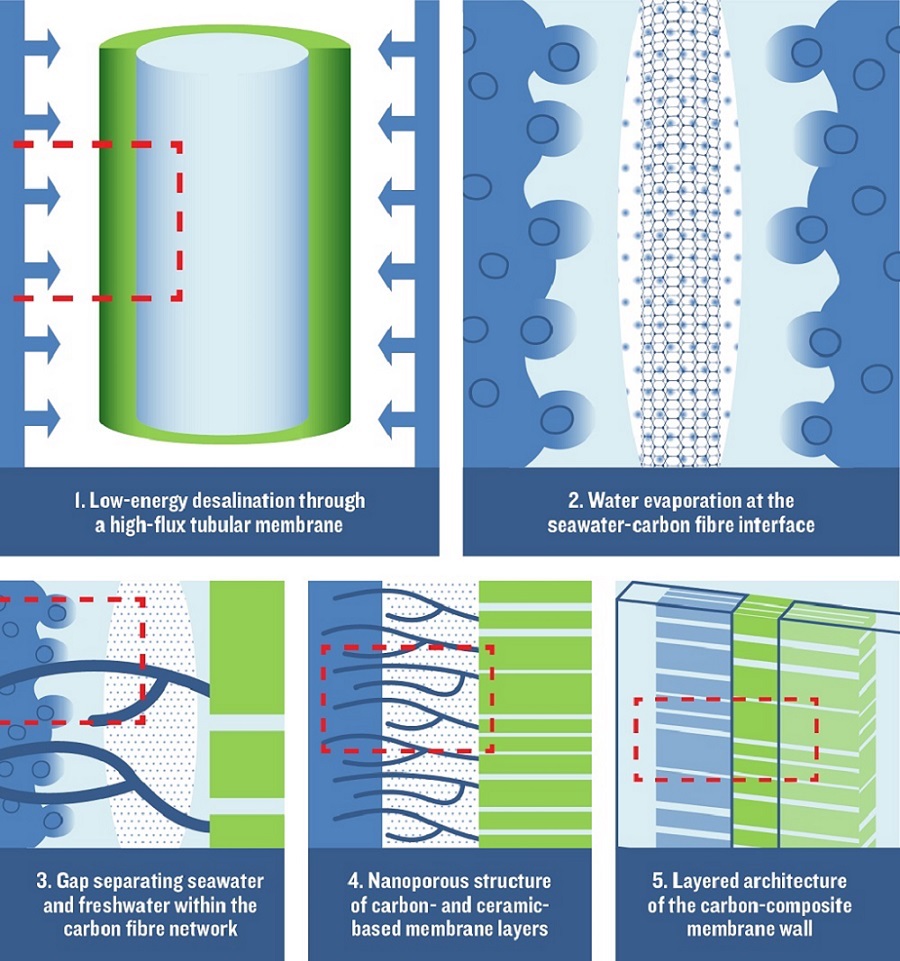

A membrane made of porous carbon-fiber structures grown on a porous ceramic substrate is more efficient at filtering seawater than existing similar membranes.

Engineered porous membranes could help recover freshwater from heavily polluted groundwater and seawater, which is of critical need in developing countries and arid environments like the Arabian Peninsula. Conventional water desalination processes rely on polymer membranes. However, if these membranes achieve very good salt rejection, they can fall short of the necessary high freshwater flux.

Zhiping Lai and colleagues from KAUST have developed carbon-composite membranes that consist of a network of carbon fibers deposited on a porous, hollow ceramic tube. These membranes are “the first that can be used in all three membrane-based desalination processes, namely membrane distillation, reverse osmosis and forward osmosis,” says Lai. These membranes can simultaneously reject all the salt plus let large quantities of freshwater through their nanoscopic pores while consuming little energy. The water fluxes are up to 20 times higher than for commercial membranes.

These results come from a unique interfacial salt sieving effect, which differs from a solution-diffusion mechanism observed in polymer membranes, explains Lai. One side of the membrane is immersed in salt water while the other is in contact with fresh water, creating a gap between two liquid surfaces. "Water evaporates from the salt water and quickly passes through the carbon gap before condensing at the freshwater side. Thanks to the excellent thermal conductivity of carbon fibers, most of the energy can be recovered, which reduces energy consumption by more than 80 percent,” adds Lai.

Originally published at the KAUST Discovery

Selected Publications

- High-flux water desalination with interfacial salt sieving effect in nanoporous carbon composite membranes

W. Chen, S. Chen, T. Liang, Q. Zhang, Z. Fan, H. Yin, K-W. Huang, X. Zhang, Z. Lai, P. She...

Nature Nanotechnology, volume 13, pp. 345-350, (2018)