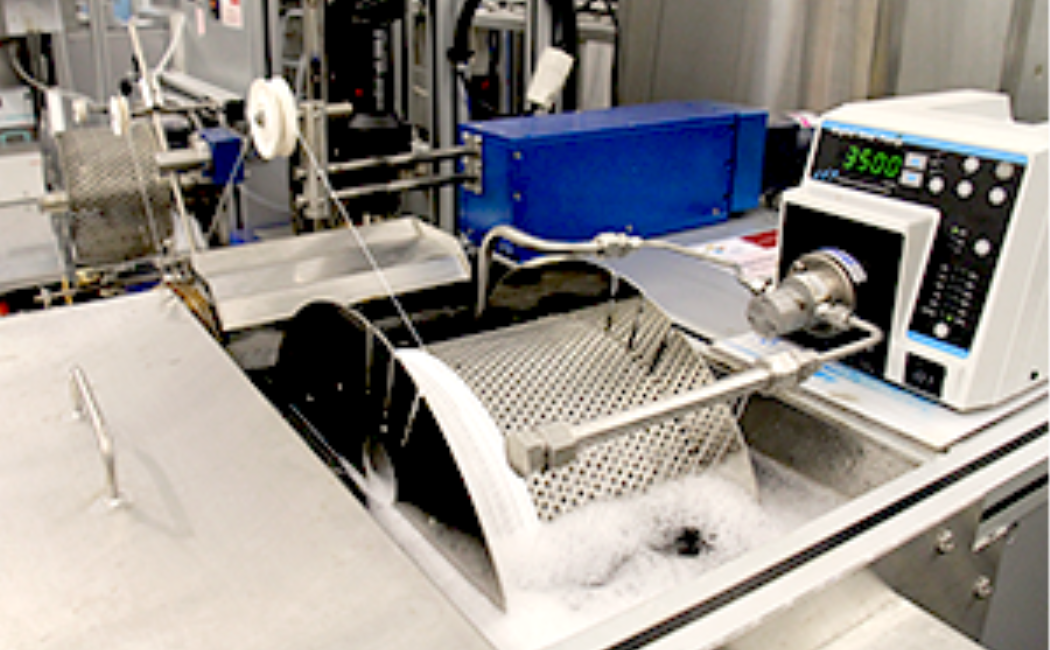

Hollow Fiber Spinning Machine

This custom-designed machine creates polymeric hollow fiber membranes using a technique called Diffusion Induced Phase Separation method (DIPS). A homogeneous polymer solution (dope) and a bore fluid (or inner coagulant) are simultaneously fed to a spinneret by a precision gear pump and a liquid pump, respectively. The co-extruded solution is immediately immersed in a coagulation bath to induce phase separation and the formation of a fiber. The nascent fiber is pulled out, collected on a bobbin and washed for complete removal of residual solvents. Additionally, a custom-designed potting station is available for making modules to test the performance of the fibers.