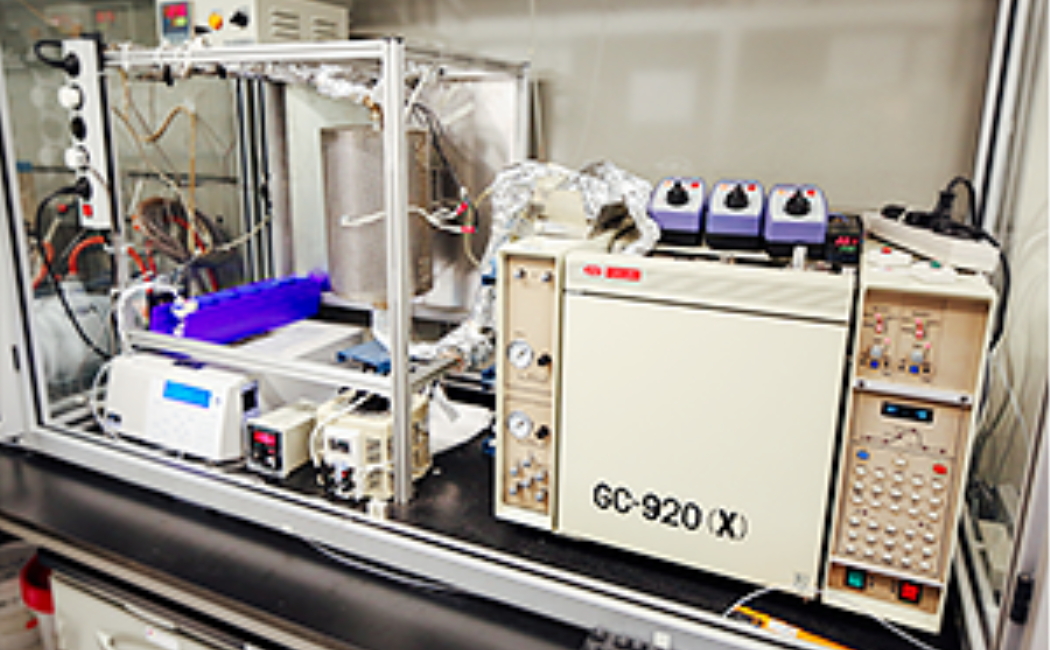

Fixed-Bed Dual Channel Microflow Reactor System

Brand: Mini-Scale, Newton & Stokes

The basic set up of the High Pressure, High Temperature Fixed Bed Microflow Reactor system is to accommodate a single furnace, and in a later stage can be upgraded to dual-furnace, micro-flow reactor in a man-height fume hood. Under normal reaction conditions, the fume hood is shut to minimize potential leakage of carbon monoxide (CO) present in the feed gas. A 6-in-1 gas cylinder trolley situated next to the reactor system securely hold 4 gas cylinders, each equipped with a 2-stage high pressure regulator to throttle the gas supply to the 4 individually calibrated (gas specified) Brooks mass flow controllers. A composite of 11 Swagelok isolation valves are installed to supply, isolate, direct, redirect gas flow direction into and around the entire reactor system in accordance to the process flow diagram.